A design update on the 33% Berkut-Long EZ that I hated to make

In this photo of an actual Berkut, notice the landing gear configuration... The nose gear on the Berkut is not steerable, but is a "grocery cart"-style free-castering assembly, mounted in a "trailing" configuration. Also, note the rearward sweep of the nose gear strut, which makes it's retraction angle approximately 65 degrees. The actual Berkut is steered by differential braking of the main gear wheels.

Now, take a look at the main gear. Made of metal, (and carbon, on some models) it is a "flat plate"-type strut, with an axle on one end and a trunion on the other. The retraction angle of the mains is also about 65 degrees.

I have done a ton of research, and have found no RC manufacturer that makes 65-degree retract units. Of course, I discussed having some custom units machined out of aluminum, but at that time, the cost was so prohibitive that I elected to solve the problem by using "standard" equipment in a non-standard way

One manufacturer I trust, and like very much, is Robart. It turns out that Robart makes the closest thing to what I needed, which is a 75-degree unit. Those are only available as main (non-steerable) gear. I have found no one who makes a steerable nose gear unit with anything close, so I was forced to attempt the nose gear installation with a 90-degree unit. The images below, from my CAD plan, show how these units would have been installed. By combining a unique mounting angle with a carefully-planned wire strut shape, (It couldn't be done with "Robo Struts") it looked like I had found a solution. (The scale Berkut "look" would have been achieved by simply gluing fiberglass strut covers over the wires.)

The nose gear problem...

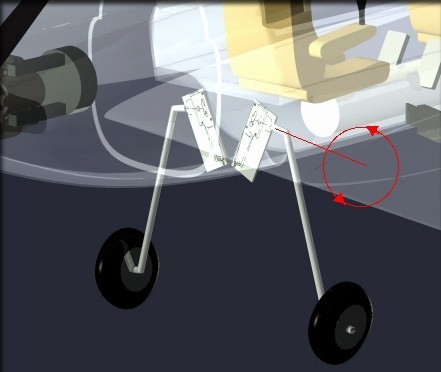

Since I didn't have a custom castering assembly, I used a standard wire. The problem is that when you turn the model on the ground, this angle causes the axle to move UP when you turn left, and DOWN when you turn right. (red arrows, above) Even using 3/16" wire, the long strut is a bit unstable, and turning it causes it to be much worse. The model sways and dips heavily in turns, and puts a lot of stress on the airframe, the retract unit, and the steering servo. I couldn't release the kit in that configuration and feel good about it.

My solution is in two parts...

For immediate use, I recommended that the nose gear, whether retractable or not, be mounted in a normal "straight up, straight down" manner, and altered the internal parts to accommodate that. Probably, only those who are serious scale competitors would care about this, and those types of modelers are likely to invent their own solution anyway.

The main gear problem...

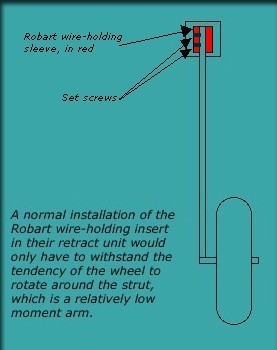

In order to use Robart retracts, you need to use some sort of "sleeve" adapter, to hold the wire strut into a landing gear block designed to hold a Robo Strut. No problem...Robart makes this part themselves, just for that reason, and in the size you need. (3/16" wire) It's a sturdy steel piece, with two set screws to hold the wire in place. Then, the retract unit itself clamps on the sleeve, as though it were a Robo Strut. As you can see in the image above, the amount of force on that sleeve is fairly low in a normal installation. ...But the Berkut isn't "normal".

With the angle of installation I had to use, the Berkut strut puts a tremendous amount of force on the sleeve, acting like a huge wrench hanging out of the plane. (red arrows, above) In testing, I thought that the wire was slipping within the sleeve, and actually welded the strut to it, to solve the problem. That didn't work either, because then all the force is directed at the (aluminum) gripping block on the retract unit, and again, it tends to collapse. This is not by any means a defect in Robart's design. It simply wasn't designed to be used in the way that I tried to use it.

My solution was to eliminate the retractable mains entirely. I would much prefer to have them, but with commercial units, it's simply not practical. A serious scale competitor who feels that they need scale gear should probably make a "one-time" set for themselves, more closely resembling the plate-and-trunion units on the actual aircraft. Since I couldn't predict the future, I left the molded-in gear door outlines, so the molded gear doors are an option, in case retracts become practical later. (or for those of you who wanted to attempt it on their own.) Tthe original (actual) Berkut models had fixed gear, just like the Long EZ, so this kit could have been used to model a Berkut, regardless of these issues.

There was some good news associated with these changes.

Adopting my solutions, several good benefits emerged:

- The model still represents a precision scale version of the Long EZ, and of the original Berkut.

- If retracts become feasible later, it could easily be converted to emulate a Berkut with retracts.

- The model is lighter, without the plumbing, air tank, extra formers required for retracts, and scale door detail.

- No air supply is required, because you can use a mechanical unit for the nose gear, along with a small retract servo, which could easily have been hidden in the nose of the model.)

- Eliminating retracts and the associated air support equipment reduces the overall project cost by at least $300.

- The plane can be flown with a standard 4-channel radio.

- The model is much easier to assemble and maintain.

- Without all the holes cut in the fiberglass parts for gear doors, the plane is stronger, without adding weight.

- Ground handling is greatly improved, and the model handled grass fields much better.

- Without all the internal air support equipment, there is much more room in the cockpit area for scale detailing.

Back to Construction page two